Pillar Shuttering Plates in Nepal: A Comprehensive Guide for Construction Professionals

1 year ago ,

Pappu Trade Concern

It is extremely important to use proper construction materials and techniques in construction. Therefore, it is important to understand the application and best practices. Among many construction equipment, Pillar shuttering plays a crucial role in supporting pillars during construction. Here we will explore the usage, maintenance, and best practices for Pillar Shuttering Plates in Nepal. That said, let's get started!

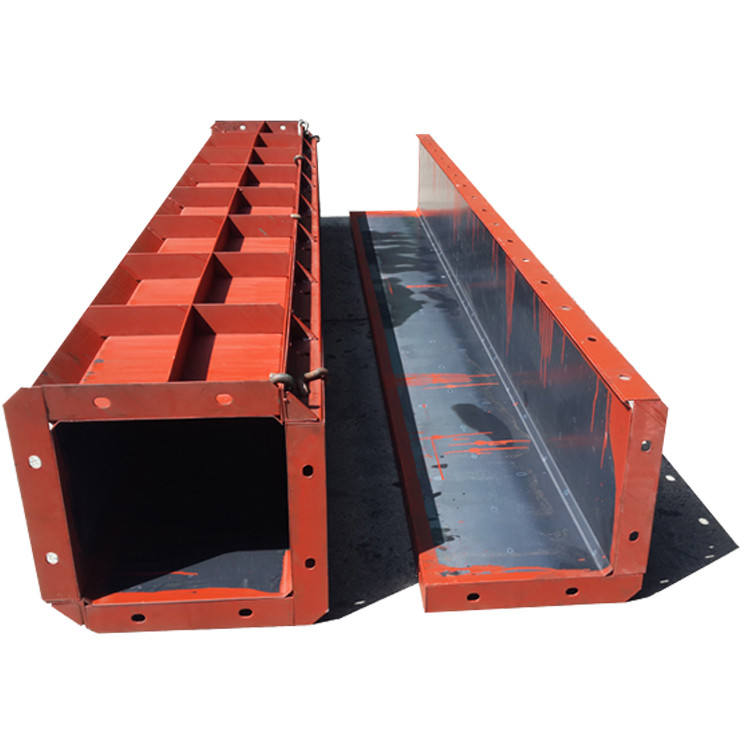

What is Pillar Shuttering Plate?

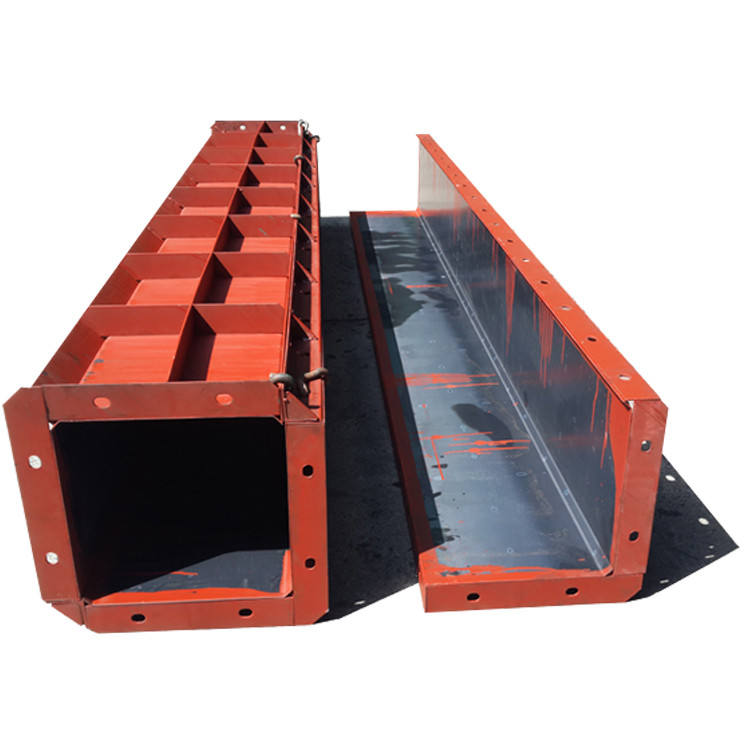

Pillar Shuttering Plate is a temporary structure used to provide mold and structural support for concrete and cement. These shuttering plates hold the concrete in fixed form and let them cure. Pillar Shuttering plates are made of durable materials such as Iron and Steel. These simple construction equipment are designed to withstand the weight.

As mentioned prior, the primary purpose of the Pillar Shuttering Plate is to provide accurate dimensions and surface. These plates also provide the required accessibility to place reinforcements bars. By using these plates, construction workers can ensure the structural integrity of the pillars.

Usage of Pillar Shuttering Plates

Pillar Shuttering Plates are designed to provide structural support and ensure proper form. These construction equipment have several usages. Some of the key usages of Pillar Shuttering Plates in Nepal are as follows:

Formwork Support

One of the key usages of Pillar shuttering plates is to act as a temporary mold to hold fresh concrete until it sets. These plates provide a strong framework for pouring and curing concrete with accurate dimensions and uniform shapes.

Load Bearing Capacity

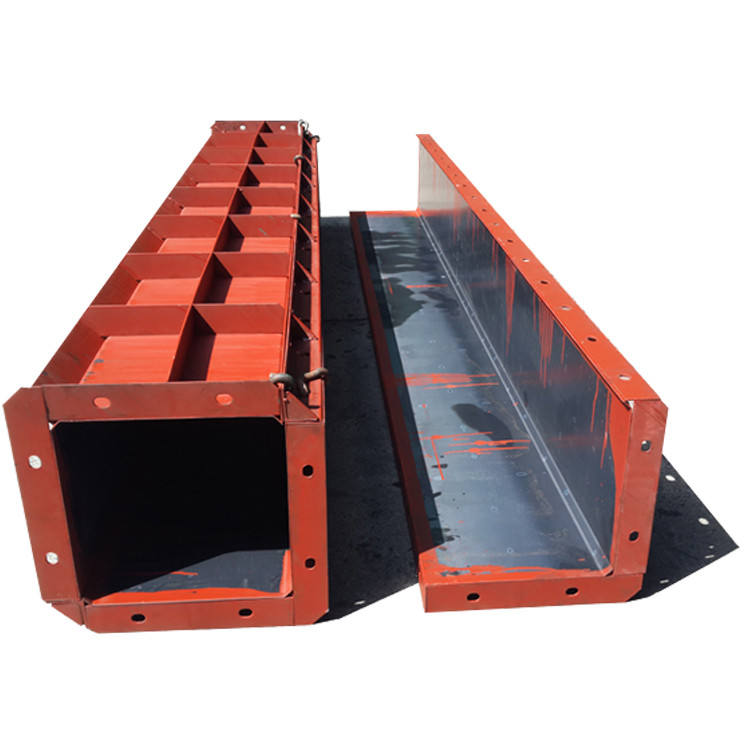

Pillar Shuttering Plates are designed to withstand high loads and pressures. Therefore, these plates are perfect for providing structural support and preventing deformation.

Reinforcement

Pillar Shuttering Plates in Nepal often come with openings or slots. These slots allow easy access to place reinforcement bars within the pillars. This ensures that the reinforcements are correctly placed, enhancing the structural strength of the pillars.

Customizability

Pillar shuttering plates allow you to customize the size and shape of pillars. These pillar plates come in a wide range of sizes and shapes. Because of the variety, you can make your pillar look attractive and unique.

Cost Effectiveness

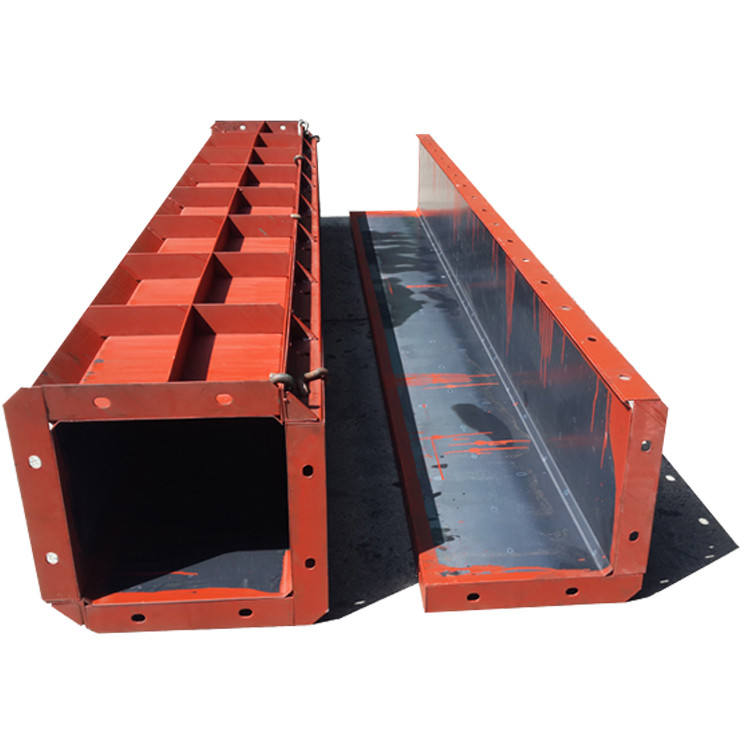

Using Pillar Shuttering Plates reduces the overall cost and time of construction projects. This is because they remove the need for traditional formwork methods such as timber which are often expensive. Additionally, since pillar Pillar Shuttering Plates can be reused, you do not need to get a new one on every construction project.

These are just some of the usages of Pillar Shuttering Plates in Nepal. Regardless, it is easy to understand why Pillar Shuttering Plates are an integral aspect of every construction.

Maintenance of Pillar Shuttering Plates

Pillar Shuttering Plates are durable and have many uses. However, even the most durable equipment needs maintenance to function properly. Pillar Shuttering Plates in Nepal are similar as well. You need to maintain Pillar Shuttering Plates occasionally to ensure their longevity and safe usage. Some of the key methods to maintain Pillar Shuttering Plates are as follows:

Cleaning

You should always clean Pillar Shuttering Plates thoroughly after each use. This will prevent dust, dirt, and oil from gathering. Additionally, cleaning Pillar Shuttering Plates also ensures that they will last longer. You can clean the plates with a brush and water or high-pressure water jets.

Inspection

After every use, you should check the Pillar Shuttering Plates for any damage and deformity. Although this construction equipment is sturdy, you can find dents, holes, or corrosion after years of use. These defects can affect the dimensions and strength of the Pillar Shuttering Plates.

Lubrication

Pillar Shuttering Plates have joints and holes for connections. When these parts get dry and rusted, it can compromise performance. Therefore, you should apply lubricants to ensure the joints, connection holes, and hinges operate smoothly.

Repairs

Besides lubricating the Pillar Shuttering Plates, regular repairing is a good way to care for these plates. If you find any damage, immediately repair or replace the broken parts. You can also reinforce the weakened parts with additional support to maintain the structural integrity.

Storage

Even the most durable material will get damaged if stored improperly. Pillar Shuttering Plates are no exception to this either. Therefore, you must store this construction equipment properly. For this, you must keep Pillar Shuttering Plates in a clean and dry plate. Remember that general pillar shuttering plates are made from either Iron or Steel, which can get damaged by long exposure to humidity. You can also use protective coatings and covers to prevent moisture from affecting the shuttering pillars. You should also stack Pillar Shuttering Plates carefully to avoid any deformation or Damage.

These are key methods to care for and maintain Pillar Shuttering Plates in Nepal.

Best Practices and Installation Tips

By now, you are aware of the usage and maintenance process for Pillar Shuttering Plates. It is indeed a highly durable and functional construction equipment. However, you must know how to use this construction equipment carefully. If you fail to do so, you can put your construction and yourself at risk. Some of the key guidelines to consider while installing Pillar Shuttering Plates are as follows:

Plan and Design

Before installing pillar shuttering plates, you must carefully plan and design the formwork system. This involves considering the dimensions, shape, and load-bearing capacity of the Pillar Shuttering Plates. You should also ensure that the plates are suitable for your required application.

Proper Assembly

Shutter plates come in parts and need to be assembled before use. A slight mistake in this process can make the structure unstable, posing a risk to the construction workers and the project. Therefore, Pillar Shuttering Plates need to be assembled properly.

Reinforcement Placement

If you need reinforcement bars on Pillar Shuttering Plates, you should ensure that reinforcement bars are properly aligned and placed. You can use spacers or supports to maintain the desired spacing between the bars.

Concrete Pouring

You should always be careful and pay attention while pouring the concrete. In this process, you should avoid heavy impact or excessive force by controlling the flow. If you fail to do this, you can deform the Pillar Shuttering Plates.

Curing

After you have poured the concrete, you should give it adequate time to cure. If you remove it too early, you will have an increased chance of damaging the Shuttering Plates and the structure of the pillars. You should also follow proper stripping procedures to safely remove the formwork.

These are just some tips you can use when installing and removing the Pillar Shuttering Plates.

Conclusion

Shuttering Plates are crucial construction equipment used to shape the pillars and support them during the curing process. Besides this, Pillar Shuttering Plates are also used for supporting framework, aligning shape and alignment, providing reinforcement and reducing the cost. However, you should properly maintain and follow processes to ensure the safety of your projects and yourself.

We hope you found this helpful. Thank you for reading till the end. And if you want further insights on construction equipments, do check out some of our other blogs.

FAQ on Pillar Shuttering Plates

Q: What are the standard size plate dimensions?

A: The standard size plate dimensions are 10.5, 11, and 12 inches.

Q: What is the thickness of the shuttering plate?

A: The specifics of the shuttering plates will vary; however, one of the most common thicknesses for shuttering plates is 2 mm/1.6 mm.