Understanding Cube Mold: Uses, Benefits, and Maintenance

2 years ago ,

Pappu Trade Concern

Cube molds or Cube Concrete molds are crucial equipment in the construction and civil engineering industry. These molds are made from metal and are used for casting concrete cubes. Additionally, the cube molds are used for testing the compressive strength of concrete. But there is more to this construction equipment. Here we will look at the uses, benefits, and maintenance process of the cube mold.

So, without further ado, let's dive in to understand cube molds.

What are cube molds?

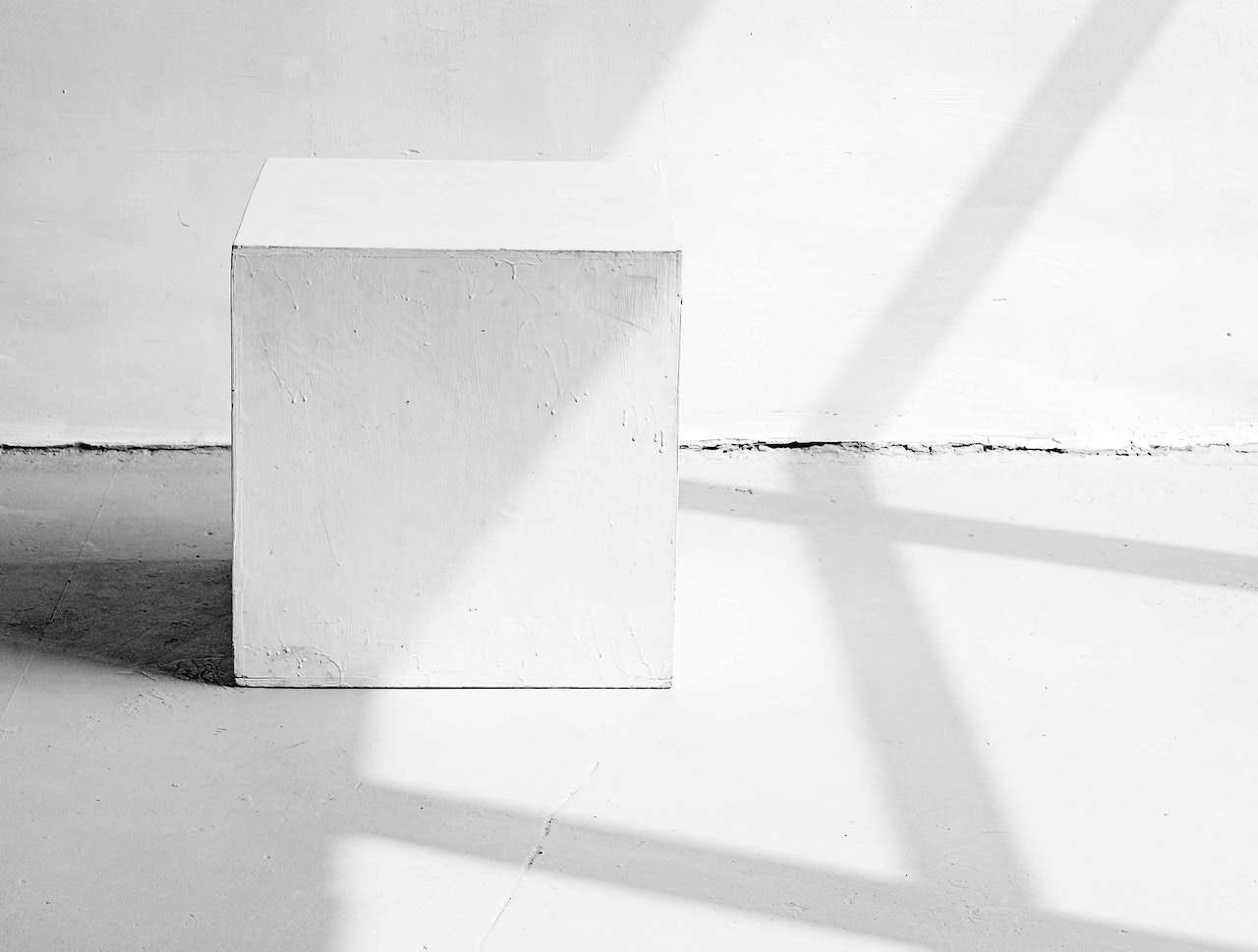

A cube mold, concrete cube mold or cement mold is a cubical container. This container is used in construction and civil engineering projects for casting concrete cubes. These molds are generally made from metal or plastic. However, they can also be made from wood at times. As their name suggests, these molds are cubical in shape and have precise dimensions.

From the above definition, it is easy to understand the primary purpose of the cube molds. But besides being used for casting concrete cubes, they are also used for testing the compressive strength of concrete as well.

These cubical molds are essential in quality control. They are also essential for ensuring the structural integrity of concrete in construction projects.

Cube mold Uses

As we mentioned earlier, one of the primary uses of cube molds is to use them for casting concrete cubes for construction. But besides these, some of the other uses of cube mold are as follows:

Testing compressive strength

One of the primary uses of cube molds is to test the compressive strength of the concrete. The concrete cubes cast using these molds are subjected to compressive strength. The results of these cube molds are then used to determine their strength and durability.

Quality Control

Cube molds are essential tools for quality control in construction projects. Cube concrete blocks are cast in different batches of construction projects. The engineers can then monitor and compare the strength of the concrete mix. This process allows the engineers to identify the issues in the concrete mixes and test for the best quality concrete mix.

Small-scale construction elements

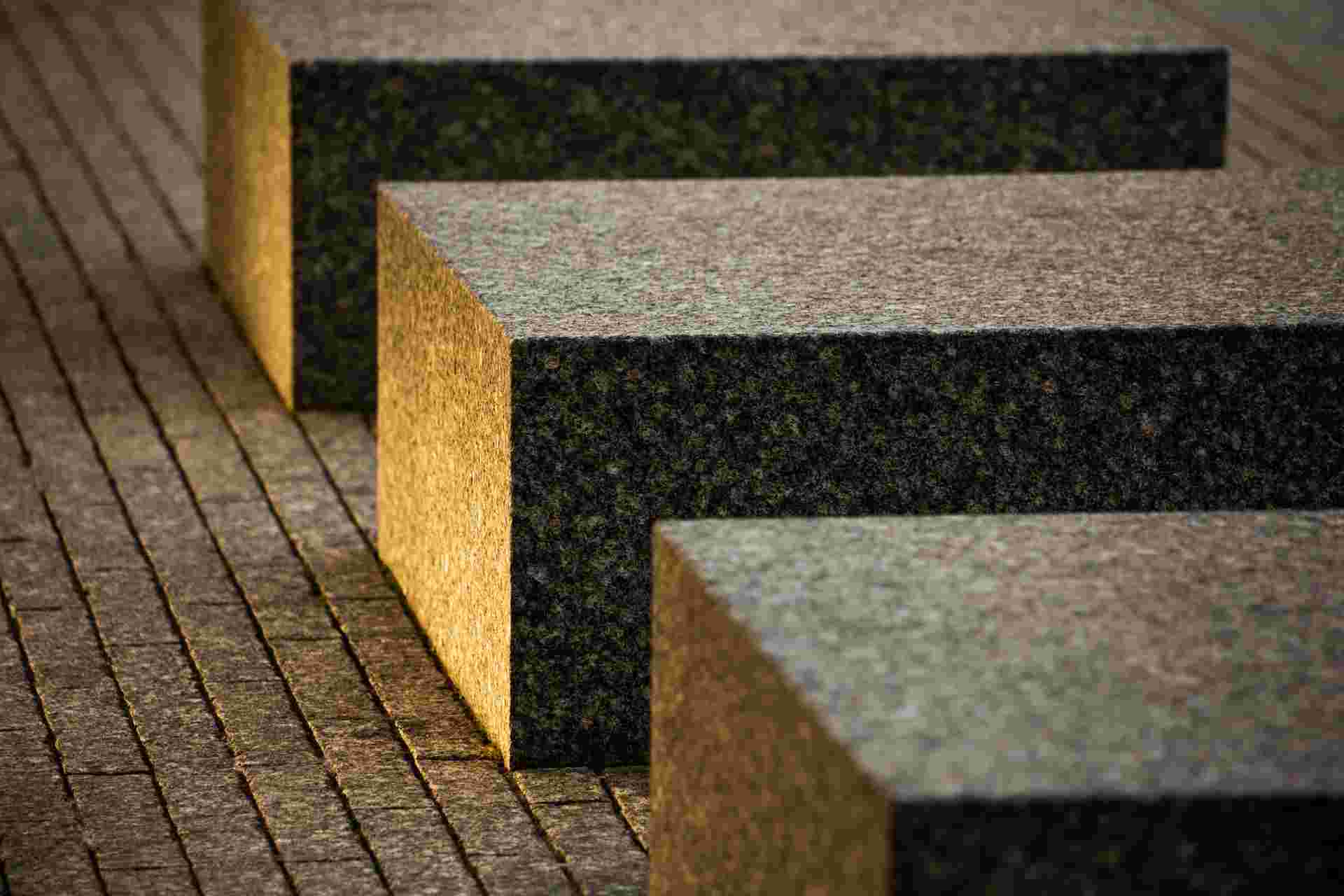

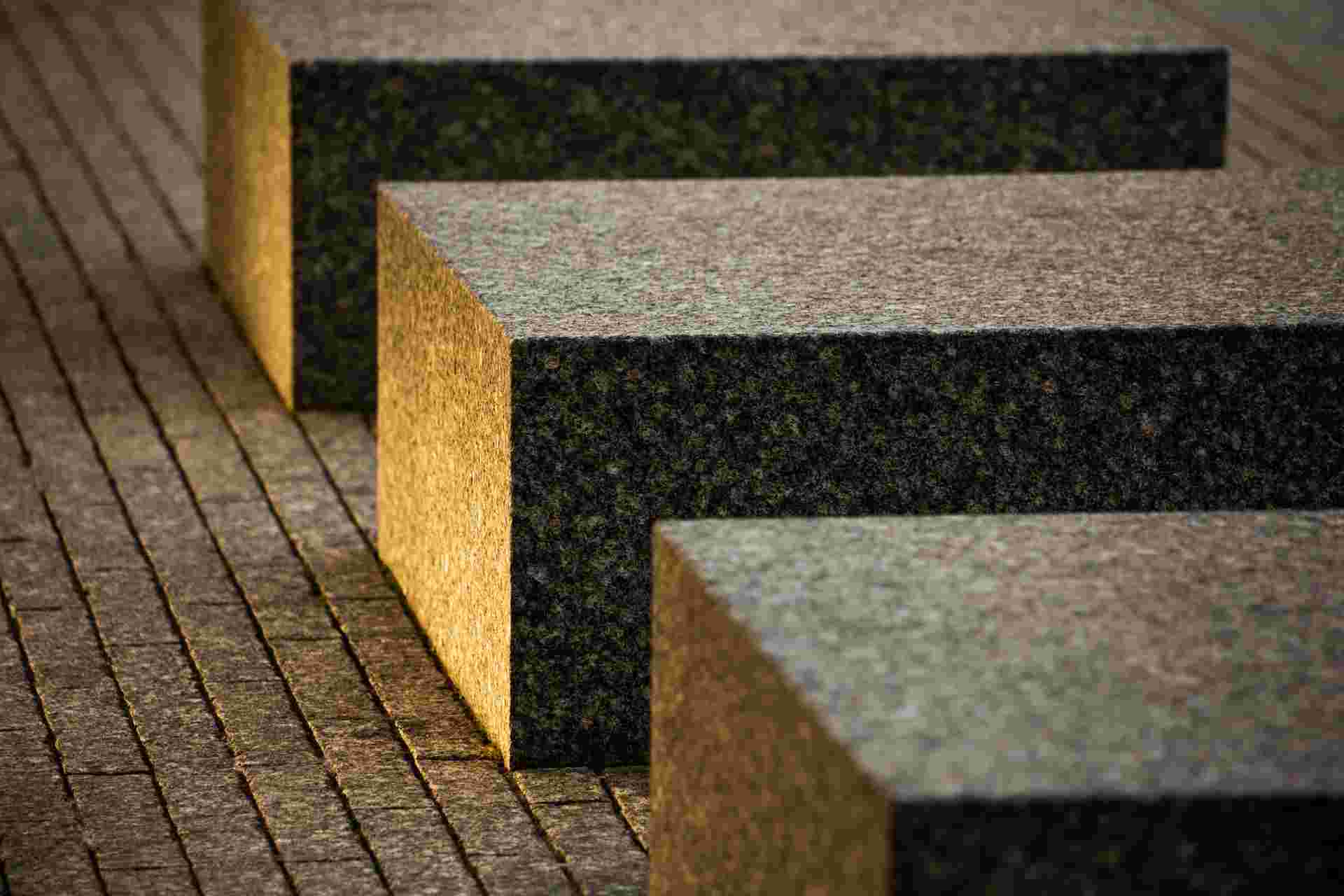

Cube molds are used widely in small-scale construction elements. These elements include paving stones, kerbstones, and decorative blocks. By using the molds, the construction workers can ensure the consistency of these construction elements. This ensures uniformity and accuracy in the final construction project.

Precast Construction production

Besides small-scale construction projects, cube molds are also widely used in precast concrete manufacturing factories. These molds are used to ensure the concrete blocks' quality and consistency. Additionally, these molds also ensure the efficiency of the production line.

Research and Development

Along with its use in construction, cube concrete molds are also used in research and development. They allow researchers to test concrete mixes, additives and curing techniques. These aspects can then be tested for strength, durability, erosion, and other properties. These molds provide a standardized shape for testing and comparison.

These are just some of the uses of cube concrete molds. As such, cube molds are an integral aspect of construction.

Benefits of Cube mold

Now that you know about the general uses of cube mold, some of you may wonder- Why use cube mold? Well, there are several benefits that cube molds provide. Because of these benefits, cube molds are widely used in the construction industry. Some of the core benefits of cube molds are as follows:

Quality Control

One of the primary benefits of cube mold is its ability to provide a standard for quality control. By regularly testing samples using cube molds, professionals can observe and test the consistency and quality of the concrete blocks. This helps the construction workers identify issues in the material selection, mixing ratios, and curing methods.

Standardized Testing

Another benefit of cube concrete molds is that they follow standardized dimensions. This ensures uniformity in the testing process. Additionally, the uniformity allows for accurate and comparable results across multiple testing sites. Therefore, it enables engineers to assess the strength of concrete blocks consistently.

Compliance with Standards and Regulations

.jpg)

Building codes often specify the need for concrete strength testing during construction projects. Since cube molds come in standardized sizes, they are perfect for complying with industry standards. Construction professionals can ensure that they comply with construction regulations and safety performance.

These are three primary benefits of cube molds. As you may have guessed, cube molds' primary benefit is providing a uniform way to cast concrete blocks. These uniform blocks can then be used for standardized testing and quality assurance.

Process of using cube molds

To ensure that you can reap all the benefits of cube molds, you must use these molds properly. The good news here is the process of using the cube molds is rather simple. To use these molds, you can follow the process below.

- Step 1: Gather all the necessary materials, including cube molds, concrete mix, a tamping rod, a trowel, a curing room/ tank, and a vibrator.

- Step 2: Clean the inside surface of the cube molds and apply a thin layer of lubricant.

- Step 3: Prepare the concrete mixture as needed.

- Step 4: Fill the cube molds with the fresh concrete mixture and eliminate the voids or air pockets using the vibrator.

- Step 5: Level the surface of the filled mold using a trowel and remove any excess concrete from the mold.

- Step 6: Cover the concrete molds with a plastic sheet or other forms of non-absorbent material to prevent moisture loss

- Step 7: Move the concrete mold to a curing tank or room.

- Step 8: Once the curing is complete, gently tap the sides or use a demolding device to remove the concrete block from the molds.

After the concrete blocks are removed from the molds, you can use them for your construction purpose as required.

Cube mold Maintenance and Care

After demolding the concrete from the cube concrete mold, you must follow the proper maintenance process. Your concrete mold will not last long if you do not follow proper care and maintenance procedures. Therefore, if you want to make your concrete molds last long, follow the cube mold maintenance and care tips below.

- Clean the concrete molds thoroughly after every use

- Do not overfill the concrete molds

- Ensure that the concrete molds are completely dry before storage

- Regularly inspect the cube molds for any signs of damage

- Store and stack the cube molds properly

- Allow the concrete to set properly before de-molding

- Keep the molds out of direct sunlight

- Store the molds in a dark and cool area when not in use

- Handle the cube molds with care to avoid any forms of heavy impacts

By following these maintenance and care processes, you can increase the lifespan of cube molds.

Conclusion

Cube molds or concrete cube molds are an integral aspect of construction projects. These molds are used to cast concrete bricks. Since these molds have standardized dimensions, they are used for a wide range of purposes and have a wide range of benefits.

Here we discussed the uses, benefits, and maintenance of the cube concrete molds. Along with this, we also talked about the process of using cube molds.

We hope you found this helpful. If you want more insights into construction accessories, check out our other blogs. And as always, thank you for reading till the end.

FAQ on Cube molds?

Q: What are concrete molds used for?

A: Concrete molds are used for casting concrete blocks in uniform and standardized dimensions.

Q: What are the different types of molds in construction?

A: The five different types of molds used in construction are:

- extrusion molding

- compression molding

- blow molding

- injection molding

- rotational molding

.jpg)